Blanching, pre-cooking, cooling… continuous thermal treatments are our other expertise. Stopping enzymatic activity, de-aerating products, setting their colour, retaining as much as possible the Brix degrees and flavours; those are all of the challenges in thermal treatments of products in tins preserved or deep frozen with an objective of food quality and safety.

We offer a large choice of machines that are designed for the better answer to the customer application which also depend on their quality and operating cost targets.

Our blanchers, blancher-coolers and coolers are designed and sized for the need:

-according to the products to be processed;

-according to whether it entails tins preserved or deep-frozen food products.

-designed for the required capacity;

-dimensions are defined on a case-by-case basis (length / width).

This equipment makes it possible to:

-blanch in hot water mode and/or in steam mode and/or in mixed mode;

-cool in water and/or cold water and/or air mode.

-Blancher-coolers can combine the various modes.

Femia's engineering office will provide you with support for customised processes

Examples of solutions dedicated to thermal treatments

The wide range of machines for thermal treatments proposed by FEMIA Industrie will allow you to opt for the most suitable solution. Discover our solutions

BR33/BR40/BR50/BR51/BR52

-Precise control of the parameters and homogeneous processing of the product by maintaining the temperature through the entire thickness of the product layer for the time required for blanching (and even pre-cooking) the processed products.

-Capacity: 500 kg/h to 20t/h according to the unit weight of the products processed and the model.

-High material yield by preserving as best as possible the organoleptic qualities of the processed products.

-Minimum water consumption according to the operating mode selected.

-Optimisation of the dimensions of the equipment according to the range of products to be processed and of the space constraints of the installation zone.

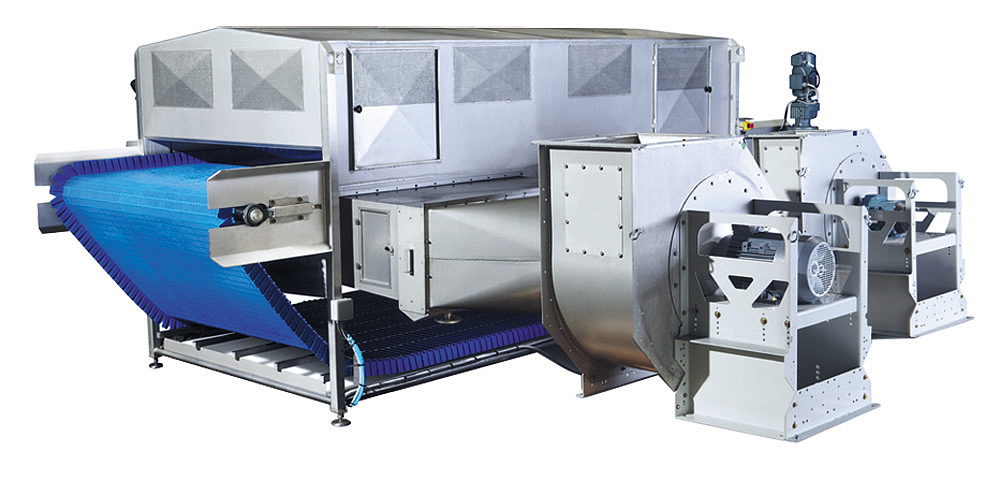

RM23

-Suitable for multiple products (except for leafy vegetables).

-Capacity: 500 kg/h to 15t/h according to the unit weight of the products processed and the model.

-Decrease in the product temperature by several tens of degrees according to the ambient temperature.

-Low water consumption, respect for the product and the environment.

-Possibility of filtering the air intake to the cooler.